Acetal Machining (Delrin ®)

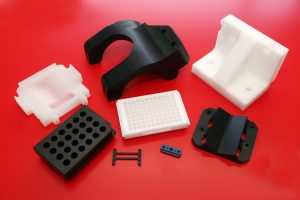

Sentinel machines bespoke Acetal / Delrin® Parts to customer specifications, through samples or drawings. Our plastic CNC machine shop specifically caters for industrial engineering plastic materials which include Delrin®/Acetal.

Read More About Our Plastic Machined Parts Process:

CNC Milled Acetal

CNC Turned Acetal

Acetal Sheet CNC Machined

Fabrication of Acetal Parts

Email Your Enquiry

CNC Machined Performance Plastic Parts· Acetal & Delrin, Nylons, PTFE Teflon, PET-P.

Acetal (Delrin®) Material

Acetal homopolymer often falls under the brand name of Delrin, from Du Pont’s ‘Delrin®’ resin. Wear resistance and lubrication are the key to longer lifetime of parts, acetal resin brings added value to applications. Consequently, Acetal allows moving parts to have have higher efficiency due to less energy loss through friction. A low coefficient of friction is created between two sliding surfaces. Sliding surfaces can bear higher loads and run at higher velocities In modified forms Acetal can replace the need for external lubricant and guarantees the right lubrication over the lifetime of the parts. Acetal has an operating temperature range of -40 to +80°C, with a tensile strength of 8,800 psi, and a melting point of 160°C. Furthermore, Acetal has an excellent resistance to oils and alcohols, but a displays a poor resistance to acids. Adhesive backing can be applied to one or both faces if needed.

Acetal in Brief

- Excellent wear resistance.

- Very low moisture absorption

- Inherently High Strength & Stiffness

- Noise reduction

- Machinability

- Resistance to chemicals

- Natural Lubricity

Types of Acetal

Acetal Copolymer

Manufactured from resin specifically formulated for wear applications, Acetal copolymer offers excellent mechanical and bearing properties plus dimensional stability, stiffness, and low water absorption. It is resistant to hydrocarbons, ketones, esters, and hot water. Standard colors are natural and black.

Homopolymer Grades

Delrin® Acetal Homopolymer properties include low water absorption and superior creep resistance, tensile strength, and fatigue endurance. It is resistant to hydrocarbons, solvents, and neutral chemicals and is recommended for bushings, fittings, impellers, and other mechanical and electrical applications.

Acetal Copolymer:

- Absorbs very little moisture

- High mechanical strength and rigidity

- Improved dimensional stability over comparable homopolymer formulations due to the lower level of crystallinity

- Low coefficient of friction

- Good compressive strength

- Good shock resistance

- Better chemical resistance with high pH solutions

- Lower centerline porosity than homopolymer in extruded shapes

- Excellent machinability

Acetal Homopolymer:

- Stiffer

- Wide operating temperature range (-40°C to 120°C)

- Higher flexural modulus at room temperature

- Higher impact strengths at room temperatures and low temperatures

- Tensile strength is approximately 10-15% higher than comparable copolymers

- Slightly higher continuous use temperature than copolymer (95°C vs. 90°C)

- Good compressive strength

- Good shock resistance

- Lower thermal expansion rate

- Better wear resistance

- Easy to machine

Acetal can be known as:

- Polyoxymethylene (POM)

- POM-C (Acetal Copolymer)

- POM-H (Acetal Homopolymer)

- Ultraform® – Copolymer brand name

- Celcon® – Copolymer brand name

- Tecaform® – Copolymer brand name

- Delrin® – Homopolymer trade name

- Polyacetal

- Polyformaldehyde

Need A Company that Machines Acetal & Bespoke Machined Parts

Call 01384 633082

Acetal Machined Parts are made in house on CNC controlled machines. These are just some examples of parts we machine from Acetal Delrin®: Acetal Medical Parts, Delrin® Buffers, Acetal Bushings, Delrin® Bearings, Acetal Guide Blocks, Delrin® Wear Pads, Acetal Washers.