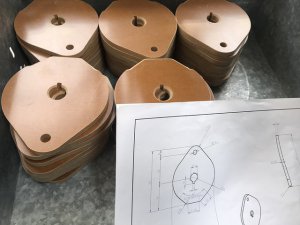

Phenolic Machined Parts

Importantly, Sentinel has been Manufacturing Phenolic Machined Parts for over 30 years. Thus, this Experience is just one of many reasons, why we consider ourselves top of the pack in this field. Certainly, the Company has the skills and the depth of knowledge required to CNC Machine the variety of phenolics available today.

Read More About Our Plastic Machined Parts Process:

Email Your Enquiry

What is Phenolic?

Firstly, Phenolics are produced when laminates, made from layers of paper, cotton cloth or Glass fibre cloth, are placed into a resin or varnish. And then, strongly bonded together.

Next, to squash the layers together, the laminated contents of the press are heated up under a very high pressure. Thus, as this happens, the resin melts and becomes gluey, sticking the layers firmly together into one solid mass. Finally, whilst still under the heat and pressure, the resin then ‘cures’, that is, it undergoes a chemical change, becoming a hard, solid Material which can no longer be melted with heat.

Grades Available for Phenolic Machined Parts

Also, using different varieties of resin with various types of cloth or paper, many different grades of Industrial laminates can be produced.

The three main types are: -,

First off, Phenolic Machined Parts made from layers of paper – known as SRBP, or ‘synthetic resin bonded paper’.

Also, Phenolic Machined Parts grades made from layers of cotton cloth – known as SRBF, or ‘synthetic resin bonded fabric’

Finally, Epoxy Glass laminate, which is the most common, grades are made from layers of Glass fibre cloth.

Common Trade Names: Tufnol, Paxolin, Bakelite, Bakelaque, Garolite, Micarta, Pertinax, Pirtoid. Furthermore, specialist Phenolic laminates, such as low smoke and halogen free Materials are available. For example, EM42.

More here

Methods of Machining Phenolic

Firstly, it is important to note that Phenolic Machined Parts can be Manufactured from Sheet, rod or tube. Ultimately, the type of Part required will then, dictate the Material requirement. And therefore, the method of Manufacture.

Most noteworthy, Sentinel Plastics Ltd can draw on many years’ Experience to produce high Quality Components. Hence, from these high specification Industrial Plastics Material.

Phenolic CNC Milled Parts and CNC Turned Parts (Rod or Tube) and finally CNC Routing flat Sheet. Most noteworthy, a large capacity of machinery is available to Sentinels Experienced and highly skilled staff. Thus, ensuring the customer can be confident of a relatively short lead time. Plus, Quality of Parts supplied. Importantly, Specifics on these methods can be found through clicking on the linked names, or on the top menu.

Phenolic Industrial Laminate Fabrication and Finishing

Certainly, with the correct adhesive or resin, Industrial Laminates can be easily bonded. Of course, Customers commonly used applications are electrical wire bobbins or switchgear and power control base plates. For sure, the excellent mechanical strength, combined with its Insulation properties, make phenolics the popular choice for Fabricated electrical assemblies.

Also, the final process in the Manufacture of Phenolic Industrial laminate Components is re-insulating surface treatment. And varnish or resin coating. Hence, the Experienced Sentinel Plastics team regularly carry out these processes.

Phenolic Machined Parts manufactured here at Sentinel.

SRBP – Phenolic – Tufnol – Insulation Plastics

Epoxy Glass

Firstly, the makeup of G10-FR4 Materials is an Epoxy Glass based Insulation Plastic. Laminates generally offer high mechanical strength and dimensional stability, are extremely durable, and maintain their properties wet or dry. Therefore, the result of this blend is a Material that offers excellent ark and track resistance.

So, the commonly known G10 / FR4 are two of the most popular grades. Generally, G10-FR4 Glass cloth reinforced Epoxy natural is typically a yellowish to light green colour. Certainly, Epoxy resins are among the most versatile and widely used Plastics in the electronics field. Primarily, due to water absorption is virtually nil. Hence, rendering it an outstanding insulator.

As a result of being the most economic choice of G10-FR4 Material, it is also noteworthy for being a Material which can be easily Machined to Bespoke applications.

Some examples of what G10-FR4 Materials are widely used to Manufacture are Insulating supports, high voltage Insulation, bus bar supports and mounting panels in electrical apparatus are just some examples.

Based on the needs of its application it comes in several grades.

Routing Phenolic Machined Parts

So, there are many advantages to using G10-FR4

Machining Materials. Most of all having high structural strength but also excellent Electrically Insulating properties.

Most noteworthy, raw Materials are available in standard sheets & rod sizes.

Finally, a couple of important factors. Firstly, Sheet thickness ranges from 0.8mm to 50mm.

Sentinel Industrial Plastics Bespoke Parts

All phenolic Machined Parts Manufactured by Sentinel Plastics Ltd are customer specific Bespoke Plastic cutting Parts. Either working from Prototypes, drawings, making a One off or hundreds of Parts. Sentinel Plastics has flexibility to meet most requirements.

As well, the Material is nearly immune to shrinkage, holding its form factor and dimensional stability at temperatures as high as 285° F. This property makes it ideal for use in electronic equipment with Components that generate excessive heat. Should it combust at higher temperatures, the bromine added during the Manufacturing process renders it self-extinguishing, another important factor for making its use in aerospace Engineering so prominent.

We are here to help!