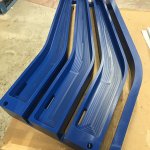

UHMW Machined @ Sentinel Plastics

November 29, 2019

UHMW Machined

UHMW Machined – Firstly, Sentinel Plastics expertly CNC Machine Ultra High Molecular Weight Polyethylene. Thus, CNC Machining takes place on either Lathes, Millers or Routers. Which, In the hands of our Experienced team, UHMW Bespoke Parts are produced. In the main, commonly, on Lathes, CNC Machined into washers & bushes. While also, CNC Millers produce intricate medical and contact food Components. Ultimately, Sentinel has the most cost-efficient Manufacturing methods available. Hence, in the hands of very Experienced Machinists, cost effective Parts are repeatedly produced.

Read More About Our Plastic Machined Parts Process:

Email Your Enquiry

UHMW Turned

UHMW Turned – Commonly, close tolerance Components are CNC Turned daily. Notably, UHMW, ultra-high molecular weight Polyethylene, is one of the most popular thermoplastics for Industrial applications. Hence, not only does it one of the highest impact strengths of the thermoplastics. Also, is highly resistant to most corrosive Materials and moisture. Lastly, it is highly abrasion-resistant, also, has an extremely low coefficient of friction and is self-lubricating.

UHMW Machined Sheet

UHMW Sheet Machined. While Polyethylene Sheet Machining takes place on 3M x 2M Routing tables. Most noteworthy, is the use of vacuum tables. Hence, able to securely hold the Materials, without the need for clamping. Thus, UHMWPE Sheet is CNC Machined without distorting the form.

Typical applications of PE1000: Including, wear strips, liners to chutes and conveyor belts. Also, aggregate handling, food processing, bottling plants and pharmaceuticals.

Finally, Polyethylene Machined Plastic is available in grades. Which, include HDPE 300, HMWPE 500 and UHMWPE 1000 grade.

UHMW CNC Milling

So, having a large capacity of CNC Milling capabilities, Sentinel Plastics Ltd can draw on many years’ Experience. Thus able, to produce high precision Components. Most important, from high specification Industrial Plastics Material. Read more

Take A Look at Our Main Engineering Plastics Processes

Sentinel Plastics Ltd is a well-established Engineering Plastics Supplier UHMW Machined and Plastic Fabrication Company based in Cradley Heath in the West Midlands. Ultimately, the Company has an already large customer base, which includes many long-term blue-chip customers.

Certainly, because it has very low moisture absorption, it is also found in some high demand areas of marine applications. It is sometimes used in some cryogenic Components due to its low operating temperature abilities. Because of its resistance to wear and impact, UHMWPE continues to find increasing Industrial applications, including the automotive and bottling sectors. Since the 1960s, it has also been the most used Material for total joint arthroplasty in orthopaedic and spine implants.

Some Advantages of CNC Machined UHMW

- UHMWPE is odourless, tasteless, and nontoxic

- Has extremely low moisture absorption

- Very low coefficient of friction

- Self-lubricating and is highly resistant to abrasion

- Very resistant to water, moisture, most chemicals

- Resistant to UV radiation, and micro-organisms

- UHMWPE only becomes brittle at temperatures below −150 °C.

Some Disadvantages of UHMW

- Its melting point is around 130 to 136 °C

- Not advisable to use UHMWPE at temperatures exceeding 80 to 100 °C for extended periods of time

- UHMWPE will deform continually if the stress is present, an effect known as creep

- Maybe not suitable for high load applications.

UHMWPE performance

- UHMWPE has an incredible resistance to abrasion and can outperform almost any Engineering Plastic in this regard

- It has a very low friction co-efficient and provides a bearing medium that is very free running and exceptionally long lasting

- Also, it is resistant to many dilute acids, solvents and cleaning agents

- It has a max operating temperature of plus 90°C and a short-term operating temperature of plus 120°C

- A very tough Material, with the highest impact strength of any thermoplastic presently made.

UHMWPE also used for

Also, because UHMWPE has excellent abrasion resistance it is often used for sand, gravel or aggregate process applications. These environments are incredibly harsh on any bearing Material, but UHMWPE is one of the few Engineering Plastics capable of withstanding such punishing abuse.

UHMWPE can also be used for low friction pulleys because of its very low co-efficient provides a bearing medium that is very free running and exceptionally long lasting. It is often found in food production environments where high volumes of containers need to be guided along conveyors or production lines.

More characteristics of UHMWPE

High speed steel tooling is recommended. With, lots of back rake. Also, a generous nose radius. Finally, use caution when Turning UHMWPE . In the main, as the chips will be continuous and tend to wrap around the tooling.

Gluing and bonding

UHMWPE does not absorb water readily, nor wet easily, which makes bonding it to other polymers difficult.

Does UHMWPE have good Wear resistance?

UHMWPE is highly resistant to abrasion, in some forms being 15 times more resistant to abrasion than carbon steel.

Chemical resistance

It is highly resistant to corrosive chemicals except oxidizing acids.

Unique characteristics UHMW

Its coefficient of friction is significantly lower than that of Nylon and Acetal, and is comparable to that of PTFE, or Teflon. Skin does not interact with it strongly, making the surface feel slippery, almost waxy.

Our UHMW Machined capacity includes but is not limited to the following: 8 No CNC Machines which includes Mazak VCN 530C + 5 No XYZ 1020 VMC + 2 Bridgeport’s VMC + 2 ProTurn Lathes + 1 Mazak Mill/Turn.

Further, For More in depth information, Follow the Quick Links below.

Sentinel Plastics Business Google – LinkedIn Plastic Machining Company – Sentinel Plastic News on Twitter